Manufacturing and Sales of

Semiconductor Application Materials

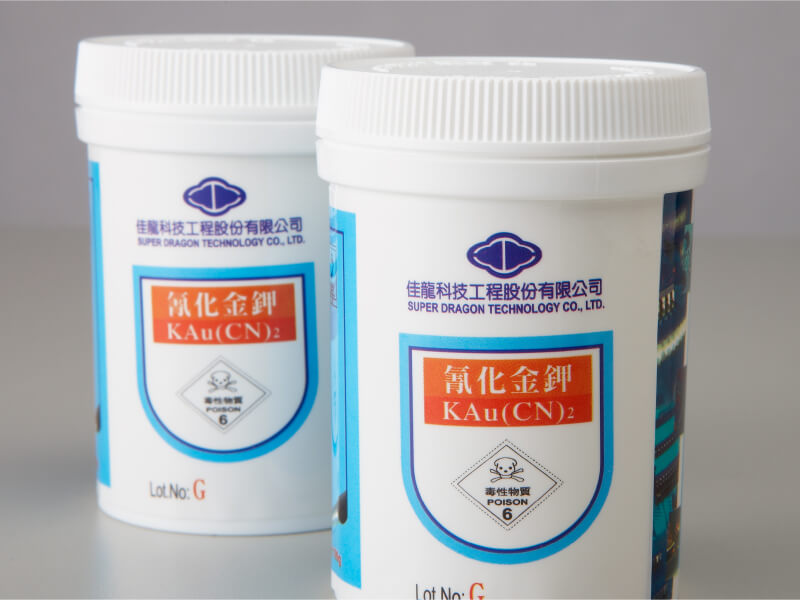

KAu (CN)2 Production

Potassium dicyanoaurate, KAu(CN)₂—commonly known as Gold Salt—is the primary material used in gold electroplating.

It has the following physical properties: soluble in water, slightly soluble in alcohol, insoluble in ether, hygroscopic, and highly toxic.

It is mainly used as a gold plating material for printed circuit boards (PCBs), connector wires, lead frames, and various electronic components used in telecommunications, military, and scientific instruments. It can also be used for decorative gold plating, electroless gold deposition, and as an analytical reagent.

Chialong’s gold salts are produced using advanced equipment and stringent quality control, achieving world-class purity and consistency.

Product Features

1. High Purity and Low Impurities — Manufactured from 99.99% pure gold bullion to ensure exceptional purity and minimal contamination.

2. Controlled Particle Size Selection — Uniform Dissolution and Enhanced Product Stability

3. Excellent Stability — Clear and Colorless Powder Form

Specifications

1. Gold Content: 68.30 ±0.05%

2. Packaging: 100 g or 40 g per container (customizable upon request)

Hazard Warnings

1. Dust or mist may irritate the nose, throat, and eyes.

2. Potassium cyanide may form hydrogen cyanide gas when exposed to moisture, which can cause mild poisoning.

3. Ingestion is highly toxic and may cause nausea and vomiting.

Safety and Protective Measures

1. Avoid inhaling dust or mist; wear appropriate protective masks and safety goggles when necessary.

2. Store in a dry, well-ventilated area to prevent moisture exposure and the formation of hydrogen cyanide gas.

3. In case of accidental contact or ingestion, seek immediate medical attention and provide the relevant safety data sheet (SDS) to medical personnel.

Target Material Manufacturing

The SDTI team focuses on the development of environmentally friendly technologies and extends its expertise into the production of application materials required in the vacuum systems industry.

Since July 2005, SDTI has been engaged in the research, development, manufacturing, and sales of PVD (Physical Vapor Deposition) sputtering targets used in thin-film vacuum systems, continuously building competitive advantages to maximize shareholder value.

We are committed to the R&D and manufacturing of thin-film sputtering materials, producing target materials tailored to specific industrial requirements. For clients with specialized process needs, SDTI analyzes and improves physical deposition characteristics through continuous innovation and technical diversification, maintaining team vitality and enhancing organizational competitiveness.

Quality Assurance

All sputtering targets produced by SDTI meet the quality standards required for various industrial manufacturing processes, ensuring precision, reliability, and consistent performance in every application.

- High-Purity Metal Sputtering Targets

- Highly Stable Metallurgical and Physical Properties

- Target Material Processing

- Customized Target Fabrication

Specifications

Industries Served

Optical Disc Industry Target Materials

Optical Disc Industry Target Materials

Silver Targets

Specifications

ARQ-920

ARQ-930

M2-98

Stella 100

Smart

Customized per Customer Requirements

Customized per Customer Requirements

Grain Size

10~20µm

10~20µm

10~20µm

Purity

4N and above (99.99% or higher purity)

4N and above (99.99% or higher purity)

4N and above (99.99% or higher purity)

Applications

CD-R

CD-RW

DVD-RAM

DVD-R

DVD-RW/+R

RF

MEMS

LD

LED lead frame connector